Description

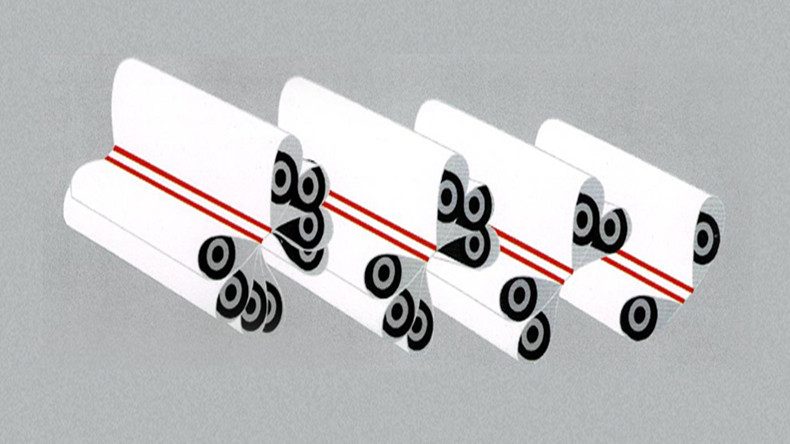

Antlink Fabric Innerduct Introduction

Fabric Innerduct is an new material pipe, it is specialized design for network construction industry.

Comparing with HDPE Sub-pipe, Fabric Innerduct is flexible belt pipe which weaved by mesh fabriC, but HDPE Sub-pipe is fixed pipe. Our Fabric Innerduct need less space in underground pipeline, so it can put more optical cable in same space pipeline with our Fabric Innerduct.

It have character of good flexible, easily installing and unrecyclable etc.

Antlink Fabric Innerduct series

●1-Cell / 2-Cell / 3-Cell / 4-Cell

●Size: 35mm / 40mm / 45mm / 50mm / 55mm

●Pulling tape: 370kg / 500kg

Application of Antlink Fabric Innerduct

Our Fabric Innerduct mainly applicate for the network construction industry of:

●Telecom

●Mobile Backhaul

●Cable TV

●Municipalities

●Power/Utilities

●Military and Government installations

●University, Corporate, and Hospital campuses

Advantage of Antlink Fabric Innerduct

●Increase the pipeline utilization rate

Save the pipeline resource and reduce the payment of pipeline.

Save the undergound space for future development.

Increase the utilization rate of communication pipeline 2-3 times.

●Easily installing

Fabric Innerduct don’t have bending memory, so it doesn’t bend like PE Sub-pipe.

Fabric Innerduct do not twisted while we install optical cable in pipeline, so it can bending

freely.

Fabric Innerduct is equipped with high strength pull tape in each cell, so it can install

more convinient.

Low requirement for construction side, so it is quite suitable for downtown area.

●Protect cable and external pipe

The tensile strength of our Fabric Innerduct is more than 1000KG.

The melting point of our Fabric Innerduct is 223℃, with a little flame retardant resistance, we also can customize strong flame retardant resistance Fabric Innerduct for our

customer.

Comparing with PE Sub-pipe, Fabric Innerduct use soft material, it can keep soft all the

year. But PE Sub-pipe will become hard when the temperature below 5℃, which will bring

troubles for installing.

The thermal expansion and contraction rate of Fabric Innerduct is 1/6 of PE Sub-pipe.

The friction coefficient of Fabric Innerduct is low than PE Sub-pipe, so it can reduce the friction between Fabric Innerduct and cable.

●The design of easy distinguish

For 2-Cell/3-Cell/4-Cell Fabric Innerduct, we use different color pulling tape for each

cell, so workers can distinguish each cell very easily while they installing Fabric Innerduct to cable. We will print meter mark in our Fabric Innerduct, so it can prevent waste in installing.

●Environmental design concept

Fabric Innerduct can use in underground for 30-50 years. For PE Sub-pipe, it will aging to

slag, and it will blocking the cables. Fabric Innerduct can avoid this problem by our

environmental design concept.

●Long time service life

The Fabric Innerduct have good chemical inertness, it can be exposed in hostile unnerground environment for very long time. The design service life of our Fabric Innerduct is 50 years, but PE Sub-pipe’s service life is only 10 years.

●Small volume, easy shipment

Fabric Innerduct’s weight is only 1/12 of PE Sub-pipe, so it can save shipment cost.

Fabric Innerduct’s volume is only 1/9 of PE Sub-pipe, so it can save warehouse cost.